- Diamond cutting

-

Part of a series on Diamonds

Material Material properties

Crystallographic defects

Formation and surfacingThe 4 Cs Carat · Clarity

Color · CutProduction List of mines

Diamond cutting

The diamond industry

De BeersCultural impact History · Symbolism

Famous diamondsImitations and enhancements Synthetics · Simulants

EnhancementsSee also Index of related articles

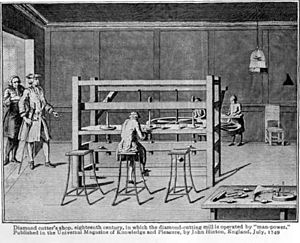

Wikipedia Commons mediaDiamond cutting is the art, skill and, increasingly, science of changing a diamond from a rough stone into a faceted gem. Cutting diamond requires specialized knowledge, tools, equipment, and techniques because of its extreme difficulty.

The first guild of diamond cutters and polishers (diamantaire) was formed in 1375 in Nuremberg, Germany, and led to the development of various types of 'Cut'. This has two meanings in relation to diamonds. The first is the shape: square, oval, and so on. The second relates to the specific quality of cut within the shape, and the quality and price will vary greatly based on the cut quality. Since diamonds are very hard to cut, special diamond-bladed edges are used to cut them. The first major development in diamond cutting came with the "Point Cut" during the later half of the 14th century: the Point Cut follows the natural shape of an octahedral raw diamond crystal, eliminating some waste in the cutting process.

Diamond cutting, as well as overall processing, is concentrated in a few cities around the world: while 80% of rough diamonds are handled in the Antwerp diamond district in Belgium, more than 50% of processed diamonds also pass through there. 92% of diamond pieces are cut in Surat, Gujarat state in India. The other important diamond centers are Tel Aviv and New York city.[1]

Contents

Diamond cutting process

The diamond cutting process includes these steps; planning, cleaving or sawing, bruting, polishing, and final inspection.[2]

Planning

Diamond manufacturers analyze diamond rough from an economic perspective, with two objectives steering decisions made about how a faceted diamond will be cut. The first objective is that of maximum return on investment for the piece of diamond rough. The second is how quickly the finished diamond can be sold. Scanning devices are used to get 3-dimensional computer model of the rough stone. Also, inclusions are photographed and placed on the 3D model, which is then used to find an optimal way to cut the stone.

Maximizing value

The process of maximizing the value of finished diamonds, from a rough diamond into a polished gemstone, is both an art and a science. The choice of cut is influenced by many factors. Market factors include the exponential increase in value of diamonds as weight increases, referred to as weight retention, and the popularity of certain shapes amongst consumers. Physical factors include the original shape of the rough stone, and location of the inclusions and flaws to be eliminated.

Weight retention

The weight retention analysis studies the diamond rough to find the best combination of finished stones as it relates to per carat value. For instance, a 2.20 carat (440 mg) octahedron may produce (i) either two half carat (100 mg) diamonds whose combined value may be higher than that of (ii) a 0.80 carat (160 mg) diamond + 0.30 carat (60 mg) diamond that could be cut from the same rough diamond.

The round brilliant cut and square brilliant cuts are preferred when the crystal is an octahedron, as often two stones may be cut from one such crystal. Oddly shaped crystals, such as macles are more likely to be cut in a fancy cut—that is, a cut other than the round brilliant—which the particular crystal shape lends itself to.

Even with modern techniques, the cutting and polishing of a diamond crystal always results in a dramatic loss of weight, about 50%.[3] Sometimes the cutters compromise and accept lesser proportions and symmetry in order to avoid inclusions or to preserve the weight. Since the per-carat price of a diamond shifts around key milestones (such as 1.00 carat), many one-carat (200 mg) diamonds are the result of compromising Cut quality for Carat weight. Some jewelry experts[who?] advise consumers to buy a 0.99 carat (198 mg) diamond for its better price or buy a 1.10 carat (220 mg) diamond for its better cut, avoiding a 1.00 carat (200 mg) diamond, which is more likely to be a poorly cut stone.

Color retention

The 253-carat Oppenheimer Diamond – an uncut diamond does not show its prized optical properties.

The 253-carat Oppenheimer Diamond – an uncut diamond does not show its prized optical properties.

In colored diamonds, cutting can influence the color grade of the diamond, thereby raising its value. Certain cut shapes are used to intensify the color of the diamond. The radiant cut is an example of this type of cut.

Natural green color diamonds most often have merely a surface coloration caused by natural irradiation, which does not extend through the stone. For this reason green diamonds are cut with significant portions of the original rough diamond's surface (naturals) left on the finished gem. It is these naturals that provide the color to the diamond.

Turnaround minimization

The other consideration of diamond planning is how quickly a diamond will sell. This consideration is often unique to the type of manufacturer. While a certain cutting plan may yield a better value, a different plan may yield diamonds that will sell sooner, and thereby returning the investment sooner.

Cleaving or sawing

Cleaving is the separation of a piece of diamond rough into separate pieces, to be finished as separate gems.

Sawing is the use of a diamond saw or laser to cut the diamond rough into separate pieces.

Bruting

Bruting is the process whereby two diamonds are set onto spinning axles turning in opposite directions, which are then set to grind against each other to shape each diamond into a round shape. This can also be known as girdling.

Polishing

Polishing is the name given to process whereby the facets are cut onto the diamond and final polishing is performed. The process takes the steps blocking, faceting, also called "brillianteering", and polishing.

Final inspection

The final stage involves thoroughly cleaning the diamond in acids, and examining the diamond to see whether it meets the quality standards of the manufacturer.

Cutting process

It is possible only because the hardness of diamond varies widely according to the direction in which one is trying to cut or grind.

A simplified round brilliant cut process includes the following stages:

- Sawing the rough stone.

- Table setting where one facet is created. The table facet is then used to attach the stone into a dop (a lapidary tool holding gemstones for cutting or polishing).

- Bruting the girdle.

- Blocking four main pavilion facets.

- Transferring to another dop in order to rotate the stone.

- Blocking four main crown facets.

- Cutting and polishing all pavilion facets.

- Transferring to another dop.

- Cutting and polishing all crown facets.

This is just one, although a fairly common way of creating a round brilliant cut. The actual process also includes many more stages depending on the size and quality of the rough stone. For example, bigger stones are first scanned to get the three-dimensional shape, which is then used to find the optimal usage. The scanning may be repeated after each stage and bruting may be done in several steps, each bringing the girdle closer to the final shape.

See also

External links

- Antique Jewelry University - A History of Diamond Cutting

- Diamond Design, Marcel Tolkowsky. Web edition as edited by Jasper Paulsen.

- History of diamond cutting

References

- ^ "The Diamond Industry". http://photius.com/diamonds/the_diamond_industry.html. Retrieved 2010-10-14.

- ^ Diamonds and Diamond Grading: The Evolution of Diamond Cutting Gemological Institute of America, Carlsbad, California, 2002

- ^ Pierson,Hugh O (1993). Handbook of carbon, graphite, diamond, and fullerenes: properties, processing, and applications. William Andrew. p. 280. ISBN 0815513399. http://books.google.com/books?id=jPT6JADCqgwC&pg=PA280.

Categories:

Wikimedia Foundation. 2010.