- Kenaf

regnum =Plantae

unranked_divisio =Angiosperms

unranked_classis =Eudicots

unranked_ordo =Rosids

ordo =Malvales

familia =Malvaceae

genus = "Hibiscus "

species = "H. cannabinus"

binomial = "Hibiscus cannabinus"

binomial_authority = L.|Kenaf [Etymology: Persian] , [ "kenaf." Webster's Third New International Dictionary, Unabridged. Merriam-Webster, 2002. http://unabridged.merriam-webster.com ] "Hibiscus cannabinus", is a plant in the

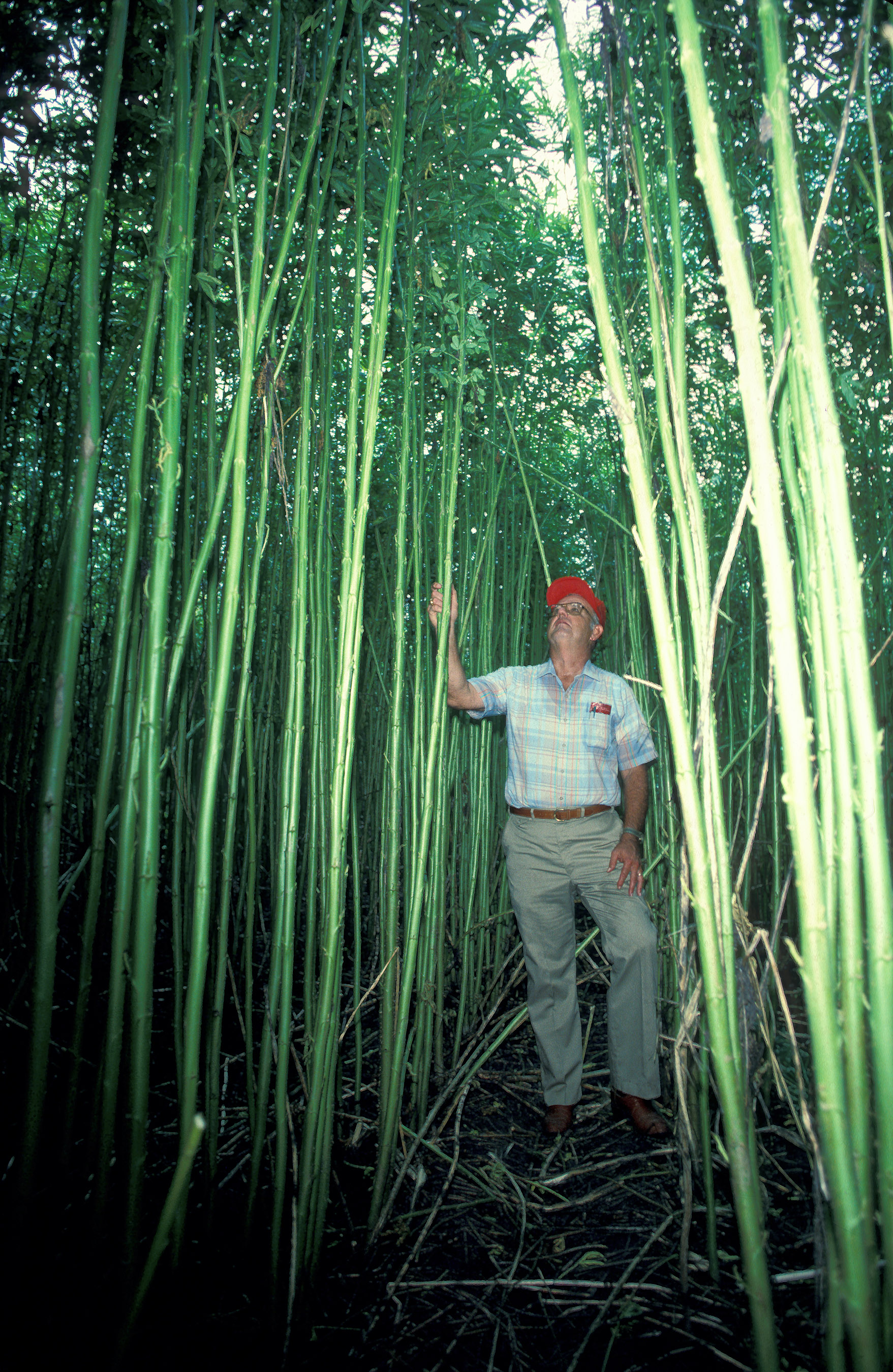

Malvaceae family. "Hibiscus cannabinus" is in the genus "Hibiscus " and is probably native to southernAsia , though its exact natural origin is unknown. The name also applies to thefibre obtained from this plant. Kenaf is one of the allied fibres ofjute and shows similar characteristics. Other names include Bimli, Ambary, Ambari Hemp, Deccan Hemp, and Bimlipatum Jute.It is an annual or biennial

herbaceous plant (rarely a short-lived perennial) growing to 1.5-3.5 m tall with a woody base. The stems are 1-2 cm diameter, often but not always branched. The leaves are 10-15 cm long, variable in shape, with leaves near the base of the stems being deeply lobed with 3-7 lobes, while leaves near the top of the stem are shallowly lobed or unlobed lanceolate. Theflower s are 8-15 cm diameter, white, yellow, or purple; when white or yellow, the centre is still dark purple. Thefruit is a capsule 2 cm diameter, containing severalseed s.Uses

Kenaf has a long history of cultivation for its fibre in

India ,Bangladesh ,Thailand , parts ofAfrica , and to a small extent in southeastEurope . The stems produce two types of fibre, a coarser fibre in the outer layer (bast fibre ), and a finer fibre in the core. It matures in 100 to 1,000 days. About 9,000cultivar s are produced Fact|date=September 2008. Grown for over 4,000 years inAfrica where its leaves are consumed in human and animal diets, the bast fiber is used for cordage, and the woody core of the stalks burned for fuel. This crop was not introduced into southern Europe until the early 1900s. Today, principal farming areas are throughoutChina ,India , and in many other countries including the following: Mackay,Australia in trial stages; [http://www.kenafseed.com Seed farms- Texas,USA and Tamaulipas, Mexico] ; [http://www.biotechmills.com/product.htm North Carolina, USA ] , [http://www.newfarm.org/international/senegal/0406/index_print.shtml, Senegal] to name a few.The main uses of kenaf fiber have been

rope ,twine , coarsecloth (similar to that made fromjute ), andpaper . In California, Texas and Louisiana, 3,200 acres (13 km²) of kenaf were grown in 1992, most of which was used for animal bedding and feed.Emerging uses of kenaf fibre include

engineered wood , insulation, andclothing -grade cloth.Panasonic has set up a plant inMalaysia to manufacture kenaf fibre boards and export them to Japan, oil absorbent (based on patent issued to H. and C. Willett), soil-less potting mixes, animal bedding, packing material, organic filler for blending with plastics for injection molding (using the technology developed and patented by Fibre Packaging International, Inc.), as an additive for drilling muds, and various types of mats, such as seeded grass mats for instant lawns and moldable mats for manufactured parts and containers.Kenaf seeds yield a

vegetable oil that is edible and high in omega antioxidants. The kenaf oil is also used for cosmetics, industrial lubricants and asbio-fuel .Kenaf paper

The use of Kenaf in paper production offers various environmental advantages over producing paper from trees. In 1960, the

USDA surveyed more than 500 plants and selected kenaf as the most promising source of "tree-free" newsprint. In 1970, kenaf newsprint produced in International Paper Company's mill in Pine Bluff, Arkansas, was successfully used by six U.S. newspapers. Printing and writing paper made from the fibrous kenaf plant has been offered in the United States since 1992. Again in 1987, a Canadian mill produced 13 rolls of kenaf newsprint which were used by four U.S. newspapers to print experimental issues. They found that kenaf newsprint [ [http://www.treehugger.com/files/2006/08/optimal_treefre.php www.treehugger.com] ] made for stronger, brighter and cleaner pages than standard pine paper with less detriment to the environment. Due partly to kenaf fibers being naturally whiter than tree pulp, less bleaching is required to create a brighter sheet of paper. Hydrogen peroxide, an environmentally-safe bleaching agent that does not create dioxin, has been used with much success in the bleaching of kenaf.Various reports suggest that the energy requirements for producing pulp from kenaf are about 20 percent less than those for wood pulp, mostly due to the lower lignin content of kenaf. Many of the facilities that now process Southern pine for paper use can be converted to accommodate kenaf.Fact|date=April 2008

USDA kenaf expert Daniel Kugler predicts that kenaf will be widely used to make paper, and that it represents a promising cash crop for American farmers. One acre of kenaf produces 7 to 11 tons of usable fiber in a single growing season. In contrast, an acre of forest (in the USA) produces approximately 1.5 to 3.5 tons of usable fiber per year. It is estimated that growing kenaf on 5,000 acres (20 km²) can produce enough pulp to supply a paper plant having a capacity of 200 tons per day. Over 20 years, one acre of farmland can produce 10 to 20 times the amount of fiber that one acre of Southern pine. [ [http://www.ars.usda.gov/is/AR/archive/aug00/kenaf0800.htm usda kenaf uses] ]

Common names

English: "kenaf" (Persian origin)India (Bengal): "mesta"India (Madras): "palungi"India (Bombay): "deccan hemp"Taiwan: "ambari"Egypt & Northern Africa: "til, teel", or "teal"Indonesia: "Java jute"Brazil: "papoula de Sao Francisco"South Africa: "stokroos"West Africa: "dah, gambo", and "rama". ["According to Miyake and Suzuta (1937), there are more than 129 names for kenaf worldwide".]

Pesticide and fertilizer use in kenaf crops

Kenaf is considered a hardy plant that requires a minimum of

fertilizers ,pesticides and water in comparison to conventional row crops. Fact|date=April 2008Notes

References and external links

* [http://www.kenafsociety.org/ American Kenaf Society (AKS)] , Founded in 1997 with individuals and organizations working directly or indirectly with kenaf and kenaf-based products, plus those with environmental concerns.

* [http://www.chinaconsultinginc.com/ CCG International (CCG), Leading International efforts to promote the use of kenaf and allied natural plant fibers.

* [http://www.jute.org/ International Jute Study Group] , A UN collaboration for learning various aspects ofJute and Kenaf. Its headquarter is located inDhaka ,Bangladesh . It targets business societies inIndia ,Bangladesh , andThailand .

* [http://www.visionpaper.com/kenaf2.html About the Kenaf Plant] , Vision Paper - Gives detailed description of kenaf plant and provides many links to kenaf industry. Pioneers in the kenaf paper industry.Produced first ever chlorine free 100% tree-free kenaf paper in 1992.

* [http://www.kenaf.de Information about Kenaf in German language] , Provides information on Market Place, News, and Links about Kenaf in German language.

* [http://www.nachwachsende-rohstoffe.info/ Nachwachsende-Rohstoffe] , A German site for Kenaf and other agricultural commodities related articles (Also available in English).

* [http://www.hort.purdue.edu/newcrop/afcm/kenaf.html Alternative Field Crops Manual]

* [http://www.naa.org/technews/tn950910/p18kenaf.html Kenaf: Taking Root? 1995 article by Brooke Wurst]

* Mabberley, D.J. 1987. "The Plant Book. A portable dictionary of the higher plants". Cambridge University Press, Cambridge. 706 pp. ISBN 0-521-34060-8.

Wikimedia Foundation. 2010.