- Belper North Mill

-

Coordinates: 53°01′42″N 1°29′13″W / 53.0282°N -1.4869°E

Belper North Mill

Strutt's North Mill built in 1803, to replace the original one destroyed by fireCotton Structural system industrialised iron framed 'fire-proof' brick Client William Strutt Coordinates 53°01′42″N 1°29′13″W / 53.0282°N -1.4869°E Construction Built 1804 Floor count 6 Floor area 127 feet (39 m) long by 31 feet (9.4 m) wide Floor usage In 1804

- Ground Floor

- Unloading

- 1st

- Spinning

- 2nd

- Spinning

- 3rd

- Carding

- 4th

- Carding

- 5th

- Reeling

- attic

- Schoolroom

Design team Awards and prizes and listings World Heritage Site Water Power Wheels 1 Diameter/ Width of Water Wheel 18 feet (5.5 m)23 feet (7.0 m) Carding Equipment 136 Other Equipment 1812

- 16 draw frames

- 4 stretching frames

- Plus reeling, doubling and twisting frames

Belper North Mill, also known as Strutt's North Mill, Belper, is one of the Derwent Valley Mills designated UNESCO World Heritage Status in 2001.

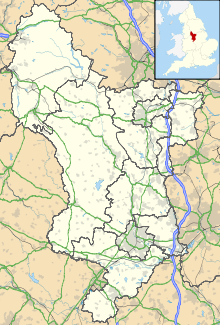

It is sited in Belper, a town in Derbyshire, England roughly half way between Derby and Matlock.

The original North Mill was completed in 1786 by Jedediah Strutt, but was destroyed by fire in 1803. Its replacement was built in 1804 by his son, William Strutt, on the earlier mills foundations and is one of the oldest surviving example of an industrialised iron framed 'fire-proof' building in the world. It is a central point in the Derwent Valley Mills World Heritage Site.[1]

Contents

Construction

This was an iron framed mill 127 feet (39 m) long by 31 feet (9.4 m) wide, 63 feet (19 m) high. It had two wings 41.5 feet (12.6 m) by 34 feet (10 m).

A cotton mill was a fire hazard, the cotton dust easily ignites and burns through the ceiling and floor timbers. This had happened to previous mill on this site. To attempt to stop this happening experiments were made to construct a fireproof mill. The floor timbers were replaced with beams of cast iron, (steel was not available till after 1860) and between them low vaults made of brick, these has a 9 feet (2.7 m) span. Above this rubble was used to level them off and a floor made of more bricks. The floor arches over the wheel pit were of a hollow clay construction.

Here the beams were cast in a "turtle back profile" to give the required strength, at minimum weight. They were held up by cast iron columns, erected on top of each other. The lateral thrust of the brick arches was resisted by concealed wrought iron ties between the column tops. The building was 15 bays wide, and the wings 6 bays wide.

This is one of the first iron frame buildings. This technology is important as it is the precursor to the steel frames used in high rise buildings. The roof was of slate and had internal gutters.[2]

The waterwheel

The breast-shot waterwheel was built by Thomas Hewes, The wheel was 18 feet (5.5 m) by 23 feet (7.0 m) wide. It was a suspension wheel with the power taken off at the edge by a spur wheel, this made it lighter than a clasp wheel. The power was transmitted to the machines by a vertical shaft, geared to horizontal shafts on each floor. Leather belts were used to connect the shafts to individual machines.

The Processes

Each of the five floors housed different stages of the cotton spinning processes.

The raw cotton bales would be unloaded from carts at the ground floor loading bay. The opening and cleaning machines broke down the bales and prepared the cotton into 'lap' form. The lap was taken to the 3rd and 4th floors.

The 1st & 2nd floors originally housed thirty-four Arkwright Water Frames each. An Arkwright Water frames spun 4236 ends simultaneously.This meant that 4236 rovings were continuously twisted together to become threads that were collected on a small bobbins. Later some of the alternative Mule Spinning machines were introduced in order to produce the finer thread types which were being demanded. The bobbins passed to the 5th floor

On the 3rd & 4th floors were the carding rooms, housing three rows of carding engines, over 130 in total. These machines disentangle the cotton fibres to produce a long continuous 'sliver'. Sixteen drawing frames straightened out the fibres. The lantern frames pilled the slivers into 'rovings' ready for spinning, on the 1st and second floor.

On the 5th floor, reeling frames wound the spun thread into 'skeins' ready for dyeing at a factory in Milford. Doubling frames twisted two or more single spun thread together to make thicker and stronger thread. The amount of twist imparted determined the thread's properties.

The attic was later used as a schoolroom.

Machinery

Machinery contained in this mill:-

- 80 spinning frames with 4236 spindles each

- 136 carding engines

- 16 draw frames

- 4 stretching frames

- Plus reeling, doubling and twisting frames[2]

References

- ^ "Strutt's North Mill Belper". http://www.belpernorthmill.org.uk/. Retrieved 2009-03-15.

- ^ a b Ree (1812). Ree's Cyclopedia. http://www.belpernorthmill.org.uk/. Retrieved 2009-03-15.

External links

- Derwent Valley Visitor's Centre - official site

- Information and photos

Categories:- Textile mills in Derbyshire

- Museums in Derbyshire

- Industry museums in the United Kingdom

- Textile museums in the United Kingdom

- Textile mills built in the 18th century

Wikimedia Foundation. 2010.