- Check sheet

-

Check sheet

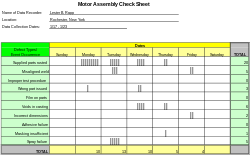

One of the Seven Basic Tools of Quality Purpose To provide a structured way to collect quality-related data as a rough means for assessing a process or as an input to other analyses The check sheet is a simple document that is used for collecting data in real-time and at the location where the data is generated. The document is typically a blank form that is designed for the quick, easy, and efficient recording of the desired information, which can be either quantitative or qualitative. When the information is quantitative, the checksheet is sometimes called a tally sheet[1] .

A defining characteristic of a checksheet is that data is recorded by making marks ("checks") on it. A typical checksheet is divided into regions, and marks made in different regions have different significance. Data is read by observing the location and number of marks on the sheet. 5 Basic types of Check Sheets:

- Classification: A trait such as a defect or failure mode must be classified into a category.

- Location: The physical location of a trait is indicated on a picture of a part or item being evaluated.

- Frequency: The presence or absence of a trait or combination of traits is indicated. Also number of occurrences of a trait on a part can be indicated.

- Measurement Scale: A measurement scale is divided into intervals, and measurements are indicated by checking an appropriate interval.

- Check List: The items to be performed for a task are listed so that, as each is accomplished, it can be indicated as having been completed.

The check sheet is one of the seven basic tools of quality control.[2]

See also

- Seven Basic Tools of Quality

References

- ^ John R. Schultz (2006). "Measuring Service Industry Performance: Some Basic Concepts". International Society for Performance Improvement. p. 3. http://onlinelibrary.wiley.com/doi/10.1002/pfi.2006.4930450405/abstract. Retrieved 2011-10-06.

- ^ Nancy R. Tague (2004). "Seven Basic Quality Tools". The Quality Toolbox. Milwaukee, Wisconsin: American Society for Quality. p. 15. http://www.asq.org/learn-about-quality/seven-basic-quality-tools/overview/overview.html. Retrieved 2010-02-05.

This accountancy-related article is a stub. You can help Wikipedia by expanding it.