- Corvette leaf spring

-

Since 1963, transverse leaf springs have been an integral part of the suspension of GM's Chevrolet Corvette. This article concerns the practical differences between leafs and coils, popular misconceptions, and the design considerations that led to their inclusion in the Corvette.

Traditional use of leaf springs

A leaf spring is a long, flat, thin, and flexible piece of spring steel or composite material that resists bending. The basic principles of leaf spring design and assembly are relatively simple, and leafs have been used in various capacities since medieval times. Most heavy duty vehicles today use two sets of leaf springs per solid axle, mounted perpendicularly to support the weight of the vehicle. This Hotchkiss system requires that each leaf set act as both a spring and a horizontally stable link. Because leaf sets lack rigidity, such a dual-role is only suited for applications where load-bearing capability is more important than precision in suspension response.

Leaf springs on the Corvette

All six generations of the Corvette have used leaf springs in some capacity. The basic arrangement for each generation is listed as follows:

- C1 (1953–1962):

- Front: Independent unequal-length double wishbones with coil springs.

- Rear: Rigid axle supported by leaf springs and longitudinal control links.[1]

- C2 (1963–1967), C3 (1968–1982):

- Front: Independent unequal-length double wishbones with coil springs.

- Rear: Independent suspension with trailing and lateral links supported by a centrally mounted leaf spring.[2]

- C4 (1984–1996):

- Front: Independent unequal-length double wishbones with transverse fiberglass mono-leaf spring mounted to allow for anti-roll effect.

- Rear: Independent suspension with trailing and lateral links supported by a centrally mounted fiberglass mono-leaf spring.

- C5 (1997–2004), C6 (2005–):

- Front: Independent unequal-length double wishbones with transverse fiberglass mono-leaf spring mounted to allow for anti-roll effect.

- Rear: Independent unequal length double wishbones with transverse fiberglass mono-leaf spring mounted to allow for anti-roll effect.

In the C2 and subsequent generations, a leaf spring is mounted transversely in the chassis and used in conjunction with several independent suspension designs. Common to these post-C1 Corvettes, the leaf acts only as a spring, and not a suspension arm or a link. Because it is not required to stabilize the wheels, the leaf functions in much the same manner as a coil spring. This configuration obviates the drawbacks and imprecision associated with leaf springs in a traditional Hotchkiss suspension layout.

Motion of a transverse leaf spring

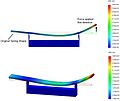

The following images show the movements of an independent suspension using a transverse leaf spring. For all images:

- The suspension arms are green

- The chassis is blue

- The uprights are gray

- Leaf springs are dark gray

- Pivot links connecting the ends of the springs to the suspension arms are red

Illustrations #1 and #2 show independent left and right leaf springs mounted rigidly to a chassis. In the first illustration, the suspension is at rest. As a left wheel moves up in the second illustration, the left spring flexes upward, but the right spring remains unaffected. Because the two springs are not connected, the movement of one wheel has no effect on the spring rate of the opposite wheel. While the C2, C3, and C4 Corvettes used a continuous spring instead of the split spring of the illustration, left and right spring rates remained independent because the spring was rigidly mounted at its center to the chassis.

Illustrations #3 and #4 show an independent suspension with a single transverse leaf spring, an arrangement similar to that used on the C5 and C6 Corvettes and the front of the C4 Corvette. While at rest in illustration #3, the leaf forms a symmetric arc between the left and right sides of the suspension with equal force applied to each. Under the compression of both wheels in illustration #4, the widely-spaced chassis mounts allow the spring to pivot; the ends of the spring flex upward and the center moves down.[3] Spring force remains even between both sides.

The leaf spring as an anti-roll bar

The extent to which a leaf spring acts as an anti-roll bar bar is determined by the way it is mounted.[3][4] A single, loose center mount would cause the spring to pivot about the center axis, pushing one wheel down as the other was compressed upward. This is exactly opposite of an anti-roll bar and has not been used on any generation of the Corvette.

A single, perfectly rigid center mount that held a small center section of the spring flat against the frame would isolate one side of the spring from the other. No roll or anti-roll effect would appear. The rear spring of the C2, C3, and C4 has this type of mount, which effectively divides the spring in two. It becomes a quarter-elliptic spring.

Beginning with the C4 model, the Corvette has had widely-spaced double mounts on the front. The rear spring has had double mounts since the C5. The spring is allowed to pivot about these two points. When only one wheel is compressed as in illustration #5, the portion of the spring between the mounts assumes a horizontal "S" shape. An impact that compresses the left wheel will tighten the bend radius of the right half of the spring, thereby lowering the spring rate for the right wheel like an anti-roll bar.[5] The caster, camber, toe-in, and general orientation of the left wheel remain unchanged.

With the Corvette's suspension configuration, the effects of the anti-roll bar and leaf spring add together at the wheels.[6] This additive property allows Corvette engineers to use a smaller, lighter anti-roll bar than the car would otherwise require if it used conventional coil springs. From Dave McLellan, chief engineer on the C4 Corvette program:[7]

We planned to use a massive front [roll] bar to achieve the roll stiffness we were after. We found, however, that by spreading the body attachment of the front suspension fiberglass spring into two separate attachments 18 inches apart, we could achieve a major portion of the roll stiffness contribution of the front roll bar for free. We still used a massive front bar, but it would have been even bigger and heavier if it had not been supplemented by the leaf spring.

Transverse leaf springs within independent suspensions

Advantages

- Less unsprung weight. Coil springs contribute to unsprung weight; the less there is, the more quickly the wheel can respond at a given spring rate.

- Less weight. The C4 Corvette's composite front leaf weighed 1/3 as much as the pair of conventional coil springs it would replace. Volvo reported that the single composite leaf spring used in the rear suspension of the 960 Wagon had the same mass as just one of the two springs it replaced.[8]

- Weight is positioned lower. Coil springs and the associated chassis hard mounts raise the center of mass of the car.

- Superior wear characteristics. The Corvette's composite leaf springs last longer than coils, though in a car as light as the Corvette, the difference is not especially significant. No composite Corvette leaf has ever been replaced due to fatigue failure, though steel leafs from 1963 to 1983 have been. As of 1980, the composite spring was an option on the C3.

- As used on the Corvette, ride height can be adjusted by changing the length of the end links connecting the leaf to the suspension arms. This allows small changes in ride height with minimal effects on the spring rate.

- Also as used on the C4 front suspension, C5, and C6 Corvettes, the leaf spring acts as an anti-roll bar, allowing for smaller and lighter bars than if the car were equipped with coil springs. As implemented on the C3 and C4 rear suspensions with a rigid central mount, the anti-roll effect does not occur.

- Packaging. As used on the C5 and later Corvettes the use of OEM coil over damper springs would have forced the chassis engineers to either vertically raise the shock towers or move them inward. In the rear this would have reduced trunk space. In the front this would have interfered with engine packaging. The use of the leaf spring allowed the spring to be placed out of the way under the chassis and while keeping the diameter of the shock absorber assembly to that of just the damper rather than damper and spring.[9]

Disadvantages

- Packaging can be problematic; the leaf must span from one side of the car to the other. This can limit applications where the drivetrain, or another part, is in the way.

- Materials expense. Steel coils are commodity items; a single composite leaf spring costs more than two of them.

- Design complexity. Composite monoleafs allow for considerable variety in shape, thickness, and materials. They are inherently more expensive to design, particularly in performance applications.

- Cost of modification. As a result of specialized design and packaging, changing spring rates often requires a custom unit. Coil springs in various sizes and rates are available inexpensively.

- Susceptibility to damage. Engine fluids and exhaust modifications like cat-back removal might weaken or destroy composite springs over time. The leaf spring is more susceptible to heat related damage than conventional steel springs.

- Perception. Due to its association with spring-located solid axles, the leaf spring has a stigma unrelated to the spring itself.

Racing concerns

- Running stiffer springs left-to-right would require either asymmetrical spring mounts or an asymmetric spring. However, a few companies such as VBP offer kits that allow independent adjustment of spring rate and ride height at all four corners of the car.

- Regulations often prohibit the use of leaf springs; NASCAR does not allow them.

- The more compact shape of a coil spring can allow for variation in more suspension design and spring placement. Because a transverse leaf spring must span the width of the car, open-wheel cars are too low to use them. The leaf spring would have to pass through the gearbox or the driver's legs.

- Coil springs are not car-specific. A Porsche, an LMP, and a Ferrari can all use a spring custom wound on the same generic equipment. Custom composite leaf springs require expensive retooling and cannot be used across car models.

- The characteristics of coil springs in a performance environment are known, and racers will use what they know. Most race teams do not have adequate experience with leaf springs to use them in this capacity.

Carroll Smith is quoted in his book, Engineer to Win

- If I were involved in the design of a new passenger vehicle, however, I would give serious consideration to the use of a transverse composite single leaf spring of unidirectional glass or carbon filament in an epoxy matrix. This would be the lightest practical spring configuration and, although space constraints would seem to limit its use in racing, it should be perfectly feasible on road-going vehicles, from large trucks to small commuter cars. (Since I wrote this paragraph the new-generation Corvette has come out with just such a spring to control its independent suspension systems-at both end of the car.)

Transverse leaf springs in other vehicles

In addition to the Corvette, a composite transverse leaf spring has been used on other GM and non-GM vehicles.

- Volvo 960 (Wagon only)

- Volvo S90

- Mercedes Sprinter vans (transverse in front only)

- VW 1-Litre-Car prototype car

- GM W platform cars- (Lumina, Grand Prix, Regal, Cutlass Supreme).

- GM E platform cars- (Eldorado, Toronado, Riviera, Reatta, Allante).

- Mercedes Smart ForTwo (used with MacPherson Struts)

- Indigo, a Swedish made, low volume roadster. Due to the anti-roll properties of the transverse leaf spring setup the car does not use a separate front anti-roll bar.[10]

Many small European cars such as the Fiat 128, the Yugo, and the Triumph Motor Company small chassis cars (Herald, Vitesse, Spitfire, GT6) used transverse steel springs in similar fashion. The Yugo's steel spring used twin attachment points and did provide anti-roll capability.

Recent patents and research utilizing dual pivotally supported composite leaf springs

In addition to the vehicles mentioned above, several automotive companies have researched suspension designs using a transverse composite leaf spring supported in a fashion similar to that of the Corvette.

- Ford Global Technologies, 2006 patent #7029017, Wheel suspension for a motor vehicle with a transverse leaf spring.[11]

- Porsche AG, 2000 patent # 6029987, Front Axle for a Motor Vehicle. Describes a strut suspension system supported by a transverse leaf spring system largely the same as that used by the Corvette. The Porsche patent mentions the beneficial stability effects of this arrangement[12]

- Honda, 1992 Transverse leaf spring type suspension patent #5141209 [13]

- DaimlerChrysler, 2004, patent #6811169, Composite Spring Design that also Performs the Lower Control Arm Function for a Conventional or Active Suspension System [14]

- ZF released a concept rear suspension design in October 2009 using a composite spring based rear suspension. The strut based suspension uses a transverse leaf spring to function as both ride and anti-roll spring. The ZF concept differs from the system used on the Corvette by using the leaf spring as one of the suspension links.[15][16]

References

- ^ http://faculty.delhi.edu/purdysd/62VettePhotos/FINF12.JPG

- ^ http://www.britishv8.org/Other/DaleRembold/DaleRembold-J.JPG

- ^ a b Lamm, Michael. P44, The Newest Corvette. ©1984

- ^ http://www.google.com/patents?hl=en&lr=&vid=USPAT6189904

- ^ Suspension, The Quest For Neutral Steer

- ^ http://en.wikipedia.org/wiki/Hooke%27s_law

- ^ Corvette from the Inside, Dave McLellan, p120

- ^ Composite leaf springs - Volvo

- ^ Schefter, James (1998). All Corvettes Are Red. Pocket Publishing. ISBN 978-0671685010.

- ^ http://www.lakritz.se/nyheter/INDIGO.PDF

- ^ http://www.google.com/patents?id=D0p3AAAAEBAJ&dq=7,029,017

- ^ http://www.google.com/patents?id=1gkEAAAAEBAJ&zoom=4&pg=PA5#v=onepage&q=&f=false

- ^ http://www.google.com/patents?id=mFYkAAAAEBAJ&zoom=4&pg=PA1#v=onepage&q=&f=false

- ^ http://www.google.com/patents?id=3kYQAAAAEBAJ&zoom=4&pg=PA1#v=onepage&q=&f=false

- ^ http://www.zf.com/media/media/en/document/corporate/press/downloads/texte_2009/tx2009-10-28_Leichtbau-Fahrwerke_zf.pdf

- ^ http://thatcarblog.com/?p=687

External links

- http://www.autozine.org/technical_school/suspension/tech_suspension1.htm

- http://www.circletrack.com/techarticles/ctrp_0602_leaf_springs/

- GM Patent #5425829- describing a method for creating variable rate composite leaf springs. Includes background information on benefits to transverse leaf springs used with conventional suspension designs

- [1] Popular Mechanics, "New steel-tough jobs for plastics in cars" July 1985

Categories:- Chevrolet Corvette

- Springs (mechanical)

- Automotive suspension technologies

Wikimedia Foundation. 2010.