- Cheng Rotation Vane CRV

-

The Cheng Rotation Vane CRV® consists of a set of stationary vanes in a cylindrical body which is placed immediately upstream of an elbow or tee in a piping system. It eliminates elbow-induced turbulence which negatively impacts the performance of pumps, compressors, and flow meters. The CRV also eliminates elbow erosion and ensures an even flow distribution to process vessels and heat exchangers which otherwise would require an elaborate custom engineered baffling system that increases pressure drop. The CRV enables the fluid to negotiate the turn through the elbow and exit with a flat velocity profile. This results in an even distribution of process fluid in the cross-section that in essence transforms the elbow into the equivalent of a straight section of pipe. The CRV® eliminates elbow induced turbulence which negatively impacts the performance of pumps, compressors, control valves, flow meters, and other equipment. The CRV® inputs to the flow a counteracting gyroscopic motion to the resultant elbow induced gyroscopic motion, and enables the fluid to negotiate the turn through the elbow and then exit the elbow with a flat velocity profile. This results in an even distribution of process fluid through any cross-section of the elbow and transforms the elbow into the equivalent of a straight length of pipe, and there is no additional pressure drop with the use of a CRV®.

Flow through a plain elbow is illustrated in the Figure 1 (a-left). As a result of the forces acting on the fluid as it passes through the elbow, two flow separation regions result where a void or vapor space is created. Because of the existence of these flow separation regions, the remaining pipe cross-sectional area through which the fluid must pass is significantly reduced, as shown in Figure 1 (b-left), and the local velocity is increased and directed towards the outer wall of the elbow. This high velocity region is one of the reasons why elbows exhibit high-pressure drop as compared to a straight pipe. Measured velocity profiles of the fluid downstream of a plain elbow at six locations are shown in Figure 1(c-left). As expected for a plain elbow, Figure 1 (c-left) shows that there is a high velocity region in the straight section of pipe along the outside of the elbow, and a low velocity/backflow region in he straight section of pipe along the inside of the elbow. When the CRV® is placed immediately upstream of an elbow, it rotates the flow entering the elbow. As a consequence, the fluid negotiates the turn with all the streamlines traveling approximately the same distance (equal flow path lengths) from entrance to exit, as illustrated in Figure 1(a-right), and the flow separation regions are eliminated. The entire pipe cross-sectional area is available for fluid flow as shown in Figure 1(b-right). For this reason, the total drop in pressure in a CRV®–plus-elbow-combination is 25% to 50% less than that of a plain elbow without a CRV®. In Figure 1(c-right), the measures velocity profile with a CRV® becomes relatively flat at the elbow exit and almost perfectly flat at a downstream position of L/D=1.25.The device addresses the flow problems listed below.

Contents

A. Pump Cavitation

Cavitation means that cavities or bubbles are forming in the liquid that is being pumped. These cavities form on the low pressure or suction side of the pump.Most pump piping systems have an elbow within ten pipe diameters of the pump’s suction inlet. The elbow causes a flow turbulence which results in pump cavitation. While the CRV® itself has no moving parts, it imparts a rotational flow to the liquid to exactly cancel the rotational effect of the elbow so that the fluid exits the elbow with no turbulence.[1]

Top view of double-suction pump showing how a plain elbow (1a) creates cavitation while a CRV® (1b) promotes an even flow distribution. In Figure 1b, a balanced, uniform flow is seen as a result of using a CRV® . The CRV® is a proven flow conditioner which has solved thousands of industrial pumping installation problems.

Top view of double-suction pump showing how a plain elbow (1a) creates cavitation while a CRV® (1b) promotes an even flow distribution. In Figure 1b, a balanced, uniform flow is seen as a result of using a CRV® . The CRV® is a proven flow conditioner which has solved thousands of industrial pumping installation problems.To operate properly Centrifugal Pumps require ten pipe diameters or more of straight pipe at their inlet, to dissipate the elbow induced non-uniform flow. When pipe diameters become large, this requirement becomes hard to meet. As a result, non uniform flow enters a pump resulting in a flow imbalance in the impeller. In the case of a double-suction pump, induced axial unbalanced vibration, head loss, and impeller cavitation occur.

Figure 2 shows the feed piping configuration of a 3,500 rpm pump utilizing an eight inch CRV®. Prior to installing the CRV® , the pumps operation had been noisy and the unit required an overhaul every 4 months. The vibration spectra of the pump before and after the installation of a CRV® are shown in Figures 3a and 3b. The dramatic reduction in measured cavitation (6-14 range on the frequency scale) also resulted in a reduction in impeller imbalance (1 on the frequency scale). This reduced the noise; extended seal, bearing, and impeller life; and increased delivered head and flow. Prior to the CRV® s installation, three identical pumps in parallel operation were required to deliver the required flow rate. After CRV® s were installed before the elbow of each pump, two pumps met the flow rate requirements, and the third pump served as an installed spare.

B. Flow Measurement Accuracy

Problems related to flow measurement accuracy include inaccurate flow measurements due to lack of space for proper installation resulting in trapped fluids in dangerous chemical concentrations.

The CRV® is a technology that provides a uniform elbow exit velocity profile, without swirl, allowing the close coupling of pipe elbows to meters. Distortion and separated flow always accompany the fluid exiting a pipe elbow. Long meter-runs are required to allow the viscous forces to re-establish a steady equilibrium flow distribution before they encounter the measuring instrument. The CRV® is a set of stationary vanes, in a cylindrical body, which is positioned upstream of the elbow. The CRV® will precisely rotate the flow about its axis to compensate for the rotation caused by the elbow. The CRV® produces a uniform and non-turbulent flow at the exit of the elbow, and allows the length of the meter-run to be dramatically reduced. Elimination of the separated pulsating flow also increases the accuracy of the meter system.[2] [3]

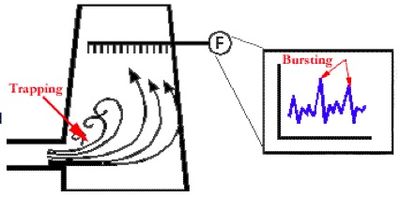

Usage example for flow meters: Continuous Emission Monitoring (CEM) is an EPA requirement for all power plants. A poor stack piping design will result in fluctuations, inaccurate pollutant readings, and burst phenomena (see Figure 1 below). This is a result of the separated flow caused by the ducting elbows in the stacks.

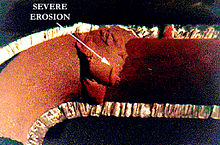

C. Elbow Erosion

Frequent elbow erosion can be caused by particulate or two-phase flow leading to unsafe elbow erosion conditions. Elbow erosion is eliminated by preventing turbulence, internal pressure gradients, and cavitation, through the use of an internally hardened CRV®. The particulates remain in the flow stream, instead of hitting the outer wall, thus cavitation induced erosion is eliminated.

D. Compressors

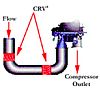

Inlet distortions cause the compressor to operate at less than the factory rated flow, head and efficiency. Interstage hunting caused by non-uniform flow. CRV® applies a lower suction piping pressure drop allowing operations closer to the factory rated flow, head, and efficiency.

Centrifugal and Fiaxial compressor operation and performance are sensitive to velocity and mass distribution at the inlet. The ASME Power Test Code for compressors (PTC-10) requires a fully developed uniform velocity profile entering the compressor OR a minimum straight run of three pipe diameters is required at the straight pipe inlet to produce a flat velocity profile. In field operations, however, compressors do not always have this ideal suction piping configuration.

Poor field suction piping includes single, double and triple elbows immediately upstream of the compressor, which create a considerable amount of distortion. For example, large multistage axial or centrifugal compressors (i.e. a refrigeration compressor) that supply high pressure systems, as shown in Figure 1, can have upstream turns in the suction piping which result in non-uniform mass and flow profiles approaching the splitter in the compressor casing.

The CRV® , when placed on the inlet side of an elbow, produces a flat velocity profile and an even distribution of process gas at the elbow exit. This allows the compressor to more closely approach its factory test inlet conditions and performance curves. Typical CRV® locations in compressor feed piping systems are shown in Figure 1 for multistage compressors and Figure 2 for interstage-cooled compressors.

E. Check Valves

Check valves, by the very nature of their design, respond to flow and pressure disturbances such as turbulence in the upstream piping system. This can result in the disc oscillating back and forth on the pin support. When a check valve is close-coupled to an upstream elbow, the turbulence becomes severe and if the oscillations are of a large enough amplitude, the disc may bang against the stop. Eventually, the pin fails, leakage though the pin starts, and the valve seat will not seal.

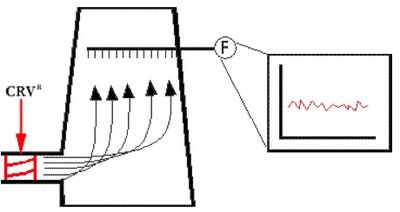

Results of time history measurements of the complex fluid pressure waves resulting from the interaction of the elbow generated turbulence and the oscillating check valve generated turbulence are presented in the figures below. Without the CRV® as shown in Figure a, it may be seen that the interaction of these two turbulant flows, results in periodically large amplitude pressure bursts. These bursts are damaging to the check valve because they result in a more severe check valve oscillation.

Results of time history measurements of the complex fluid pressure waves resulting from the interaction of the elbow generated turbulence and the oscillating check valve generated turbulence are presented in the figures below. Without the CRV® as shown in Figure a, it may be seen that the interaction of these two turbulant flows, results in periodically large amplitude pressure bursts. These bursts are damaging to the check valve because they result in a more severe check valve oscillation.F. Water Hammer

Water hammer is actually a travelling pressure wave. It is initiated by the rapid stoppage of an incompressible flowing liquid in a piping system. For example, the pounding heard in process piping usually occurs due to a rapid valve closure or when large steam bubbles are introduced into water and the water rapidly collapses the steam bubbles. These pressure waves reflect back-and-forth between the interior wall of a piping system, reinforcing themselves as succeeding waves encounter each other. These waves become so energetic that catastrophic structural damage can occur.

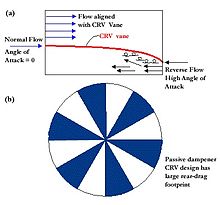

The CRV® s geometric features prove extremely useful in controlling water hammer. When fluid is flowing in the forward direction, the CRV® is passive and offers no pressure drop and keeps the flow laminar. But when the fluid travels backward, it will exhibit a high pressure drop and it will not remain attached to the vanes of the CRV®. This high drag footprint for a backward flowing fluid and travelling pressure wave, acts as a passive dampener controlling the water hammer.

Dramatic improvements were seen in a piping circuit with four elbows between the supply line and the shut-off valve where the wall static pressure, with and without CRV® s, was measured. The results indicate that with CRV® s in place upstream of each elbow, the amplitude of the peak pressure pulse was 49% of that without CRV® s.

G. Specifiying CRV®

The Cheng Rotation Vane (CRV® ) must be located right at but no further than one pipe diameter away from the elbow's inlet. With this arrangement there will be a uniform velocity profile with no downstream residual rotation.

Depending on the application, the CRV® is designed to address specific flow requirements such as velocity distribution, separation (which has accelerated and reverse flows), noise, vibration, erosion, elimination of turbulence, and pressure drop reductions.

Materials of Construction The CRV® can be manufactured from most commercially available materials, pipe diameters, pipe schedules and end connections. N-stamped units are available for nuclear applications. Special internal coatings and finishes are also available.

Dimensions CRV® - standard unit dimension in 2" to 12" sizes.

External Links

- Technology Applications

-

CRV Improves Automotive Engine Performance Supercharger

CRV Improves Automotive Engine Performance Supercharger

-

Cheng Fluid Systems

Cheng Fluid Systems

References

Categories:

Wikimedia Foundation. 2010.