- Chip formation

-

Chip formation is part of the process of cutting materials by mechanical means, using tools such as saws, lathes and milling cutters.

An understanding of the theory and engineering of this formation is an important part of the development of such machines and their cutting tools.

The formal study of chip formation was encouraged around World War II and shortly afterwards, with increases in the use of faster and more powerful cutting machines, particularly for metal cutting with the new high speed steel cutters. Pioneering work in this field was carried out by Kivima (1952) and Franz (1958). [1][2]

Chip formation is usually described according to a three-way model developed by Franz. This model is best known within the field of machine tool design, although it is also used when an application area, such as woodworking, requires a vocabulary to describe chip formation in more detail than is usually attempted.

At the start of chip formation process,the section of cutting penetrates the material, causing it to deform elastically and plastically. After the maximum limit of shear stress is reached, the material flows.dependent on a given cutting plane geometry, the deformed material results in a chip being formed, which runs off the rake face of the cutting plane.

The plastic deform-ability of not only related to the material; it can also be brought about by targeting the altering of the stress. The amount of stresses in dependent on the feed velocity, the speed of cutting, and the depth of cut. The direction of the plane of cutting is found out by defining the tool normal rake angle, the tool cutting edge angle and the tool cutting edge inclination.

In order to ensure the chip formation takes place, a minimum thickness of the chip as well as the cut depth must be exceeded.[3]

Theory of Chip Formation

The material which is exactly in front of the tool is bent upward and is compactly compressed in a narrow shear zone. For most analysis, this area of shear can be simplified to a plane.

As the tool is moved forward, the metal ahead of the tool passes through this plane of shear. If the material is ductile, there will be no fractures or cracks and the chip will be in the form of a continuous ribbon. If the material is brittle, the chip will fracture when enough time is elapsed and separate chips will be formed. It is within the shear zone that overall deformation of the material takes place which helps the chips to be removed. As on the stress-strain diagram of a metal, the elastic deformation is followed by plastic deformation. The material will have to break or yield if enough shear is applied. As the material flows from the bulk of the work piece to the shear area, it is violently sheared, and then continues into the chip section.[6]

Chips are formed by the shearing of metal in an area upstream from the tool's cutting edge, which is located on both sides of a plane, forming an angle φ with the direction of the cut.

There are 3 main areas:

- The primary shearing area, where the material is plastically deformed. It also heats up considerably.

- The secondary shearing area, which is located at the interface between the chip and the tool. This is an area where friction and slipping occur, which leads to crater wear in the tool. Considerable work hardening in this area is experienced by the internal face of the chip. Friction between the tool and the chip causes a built-up edge to form, which disappears at higher speeds to be replaced by the secondary shearing area at low cutting speeds.

- The tertiary shearing area between the flank and the machined surface. This gives rise to flank wear, due to the springback of the material after the tip of the tool has passed over it.[7]

Machining

Machining is a half-finishing or finishing process essentially done to change the material into required or stipulated dimensional form with accuracy and surface finish to enable the product to fulfill its basic functional requirements,show better or improved performance and have long life ie can be used for a long time.

Machining is a process of slow removal of excess metal from the preformed blanks in the form of chips.

The formation of the chips is an important part of machining because it directly or indirectly indicates :

- Nature and behavior of the work metal under machining condition

- Specific requirement of energy (amount of energy required to remove unit volume of work material)

- Nature and degree of interaction at the chip-tool interfaces.

The form of machined chips depend mainly upon :

- Work material

- Material and geometry of the cutting tool

- The speed of cutting, ie its velocity and feed and also to some extent the depth of cut

- Environment or cutting fluid that affects temperature and friction at the chip-tool and work-tool interfaces.[8]

Mechanism of Chip Formation

The basic mechanism involved in chip formation is that of shear deformation that si on the local area on the work material just beforeof the cutting edge of the tool. The relative motion between the tool and the workpiece during cutting pushes in the work material near the tool and thus brings about a shear deformation (called the primary deformation), which forms the chip. The chip passes over the face of the rake of the cutting tool and receives more deformation (called the secondary deformation) because of the shearing and sliding of the chip against the tool. These two plastic deformation processes depend on each other. The element that rubs the face of the rake has been heated and plastically deformed during its passage through the primary shear process; hence, the secondary process depends on the phenomenon on the shear plane. At the same time, the shear direction is directly dependent by the rake face deformation and friction processes. The shear direction thus decides the heating and straining of the chip in the primary process. Using metal cutting theory, this means that shear stress and shear direction must be determined at the same time. Such theoretical analyses are usually based on the mechanics of the process. [9]

Chip classification

There are two types of classification:

- The Original Classification

- Modern day Classification

Original classification by Dr Norman Franz

The type of chip formed depends on many factors, of both the tool and the material. In general, the main factors are the angle formed by the edge faces of the tool and also the angle at which this is presented to the surface.

Sharpness of the cutting tool does not usually define the type of chip, but rather the quality of the chip, and the clear distinctions between types. A blunt tool produces a degenerate chip that is large, torn and varies from one means of formation to another, often leaving behind a poor quality surface where this means changes.

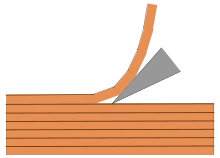

Type I chip

Type I chips are formed when a material splits ahead of the cutting edge, owing to some upwards wedge action of the tool exceeding the tensile strength of the material, perpendicular to the surface. They are thus particularly important in fibrous materials, such as wood, where individual fibres are stong but they may be levered apart relatively easily. Type I chips are generally formed by tools with shallow cutting angles.

Type I chips may form long, continuous swarf, limited in size only by the length of cut.

This is the idealised chip formation for wood shavings,[5] particularly those produced by a well-tuned plane with a finely adjusted mouth.

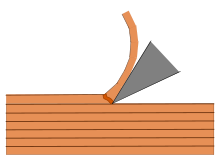

Type II chip

Type II chips are formed when a shearing force is produced by the wedge of the tool angle. The material fails along a short angled plane, from the apex of the tool edge, diagonally upwards and forwards to the surface. The material deforms along this line, forming an upward curling chip. These chips are generally formed by intermediate tool angles.

Type II chips may be formed in ductile materials, such as metals.

Type II chips may also form long, continuous swarf.

Type III chip

Type III chips are formed by a compression failure of the material, ahead of a relatively obtuse cutting angle, approaching 90°. In some weak or non-ductile materials this may form an acceptable chip, usually as a fine dust, but often it gives rise instead to a random "snowplough" effect where the waste material is bunched up ahead of the tool but not cleared decisively away as a well-formed chip.

This type of chip is formed by routers. It is also formed by woodworking scrapers, although when properly sharpened and used, these form such a thin Type III chip that it instead appears as a well-formed Type II chip. Their waste chip is thin enough that the compression failure volume is small enough to act as for the well-defined shear plane of the Type II.

Type 0 chip

This type was characterised later, by William McKenzie (1960).[note 1]

The Modern Day Classification

During the machining process, 4 basic types of chips are formed:

- Discontinuous

- Continuous

- Continuous with Built up edge

- Serrated[10]

Discontinuous Chip Formation

Discontinuous chip formation normally occurs during the machining of brittle work material (for example: glass and silicon). These type of chips also occur when machining is done using cutting tools with small rake angles, coarse machining feeds (large depth of cut), low cutting speeds and also when a lubricant or cutting fluid is not used.They are formed when the amount of deformation they undergo is limited because of continuous repeated fracturing. The metal that is deformed instead of continuously flowing gets ruptured periodically. Discontinuous chips provide better surface finish as compared to the other chips. However,in the case of ductile materials, they lead to continuously changing forces, resultant vibration and chattering in the machine tools and therefore results in a final workpiece with poor surface finish and loose tolerance.

When brittle materials, (eg. cast iron) are cut, the deformed material gets fractured very easily and therefore the chip is formed in the form of discontinuous segments. In discontinuous chip formation, the deformed material gets ruptured periodically, instead of flowing continuously. he chip leaves the tool that is used as small pieces of metal resulted from cutting brittle metals such as cast iron and cast brass with tools having extremely small rake angles.[11] [10][12]

Continuous Chip Formation

Continuous chip formation is normally considered to be the ideal condition for efficient cutting action as it gives excellent finish and occurs usually for ductile metals. The chip consists of a continuous "ribbon" of metal which flows up the chip-tool zone. It usually occurs at high cutting speed and rake angle, and a narrow shear zone.The continuous chips are normally produced when steel or other highly ductile metals are machined at very high cutting speeds.Continuous chip formation is possible because of the ductility of the metal, which flows along the plane of shear instead of rupture. Use chip breakers during the machining to prevent the chips from entangling with the tool holder. This process thus leaves the tool as a long ribbon and is extremely used when cutting most ductile materials such as mild steel, copper and Aluminium.[11]

Some ideal conditions that promote continuous chip formation:

- sharp cutting edge

- small chip thickness

- larger rake angle

- high speed of cutting

- ductile metals

- less friction between work- tool interface through lubrication[10][12]

Continuous with Built-up Edge Chip Formation

Continuous chips with built-up edge is nearly the same as continuous chips. However, during the continuous chip formation, as the metal flows up the chip-tool zone, small particles of the metal begin to stick or weld themselves to the edge of the cutting tool. As the particles continue to weld to the tool, it directly affects the cutting action of the tool. This type of chip formation is common in machining of softer non-ferrous metals and low carbon steels. Main problems are the built-up edges breaking off and being embedded in the workpiece during machining, decrease in life of tool and final poor surface finish of the workpiece.

Built-up-edge (BUE) forms when there is a chemical affinity between workpiece and the tool, such as in cases of high strain-hardening, low feed speed, large depth of cut, low rake angle and high temperature. Here, the chip becomes unstable, breaks up, melts and then forms again. The process is repeated continuously. Built up edge chip formation during machining would degrade the surface finish and changes the tool geometry.

Conditions that induce BUE formation:

- low cutting speed

- high feed

- low rake angle

Studies on the built-up edges have shown that the chip material is welded, deformed and then deposited onto the rake face of the tool layer by layer. It is thus possible to observe the presence of built-up edges by studying the back face of the chip during the machining process. This is normally used in micro or ultra precision machining operation.

To reduce built-up edges, lubrication should be done, sharp and good surface finish tools should be used and also apply ultrasonic vibration during the machining process.

This is a chip to be avoided at all costs and is caused by small particles of metal from the workpiece becoming welded to the tool face under high pressure and heat. The phenomenon results in a poor surface finish and damage to the tool.[11][10][12]

Serrated Chip Formation

Serrated chips are formed during the machining of semicontinuous material with zones of high and low shear strains. It normally occurs in metals where the strength decreases sharply with temperature. An example would be titanium.[10]

Factors affecting Chip formation

Material of work piece : Brittle materials produce discontinuous chips. On the other hand, ductile materials produce continuous chips.

Velocity : The temperature at the tool point is directly affected. But this doesn't affect the direction of chip flow. Low speed cutting causes discontinuous chips while high speed cutting leads to continuous chips.

Depth of cut and feed : Increasing the feed and DOC leads to greater distortion in the chip formed. High vales of DOC and feed also lead to the formation of BUE ( Built up edge ) and poor surface finish..

Friction in metal cutting and tool dimensions and geometry also affect chip formation.[13]

Chip thickness ratio and velocity relationships

The ratio of depth of cut ie feed in case of turning operation to the chip thickness is called chip thickness ratio.

The velocity of the chip with respect to the tool is called Chip velocity. The velocity of the tool with respect to is called the cutting velocity. The velocity of chip with respect to the work piece is called Shear velocity.[13]

Feeds and Speeds

The important parameters for all metal-cutting processes, "speeds and feeds". In a metal-cutting process the term "speeds and feeds" refers to the speed, feed, and depth of cut .

Speed is a scalar and is defined as the distance traversed in a defined interval of time. Cutting speed is the rate at which the point on the circumference of the work piece travels past cutting tool. It is measured in terms of inches/min, feet/min, meters/second, or meters/min. But, according to the SI system of measurement it is termed in meters/second.

The amount of material removed per revolution or in each pass of the tool over the work-piece is called feed. Feed is measured in units of length/revolution, length/pass, length/time, length/tooth or other appropriate unit for the defined process.

The depth of cut, DOC is the the depth that the tool penetrates into the surface of the work-piece. The DOC is half of the difference in the initial and final diameters.[14]

Speeds and feeds are very important because they are critical input parameters that define the output of a machine tool thus in turn deciding the type of chip formed.[15]

Chip Breaker

A chip breaker is used to break the continuous chip into smaller sections so that the chips cannot tangle or stick around the cutting tool. The simplest form of chip breaker is made by freshly grinding a groove on the tool face a few millimeters behind the cutting edge.[11]

Following are the principles and methods of chip breaking:- Self breaking : This is achieved without the use of a separate chip-breaker, either as an attachment or an extra geometrical tool modification.

- Forced chip breaking by the use of additional geometrical features or devices of the tool.

Self Breaking of chipsIts free and generated (rubbed) surfaces and temperatures which are not equal and cooling rate at the two surfaces. The radius of curvature increases when the cutting velocity and rake angle (positive) are increase, which is even more dangerous. When oblique cutting is done due to presence of inclination angle or restricted cutting effect etc. the curled chips tend to divagate laterally which results in the formation of helical coiling of the chips.

Forced chip-breaking

Due to work hardening and cooling done on the hot continuous chip, it becomes hard and brittle at a distance from its origin. If the running chip may not break, if it does not become enough curled and work hardened. Then in this situation, the running chip is forced to bend or closely curl so that it will break into pieces at periodic intervals. Such types of broken chips are of proper size and shape, which may differ according to the configuration of the chip breaker.

Types of chip breakers- In-built type

- Clamped or attachment type

In-built breakers are in the step or groove form at the rake surface near the cutting edges of the tools. Such chip breakers are delivered

- either after they are manufactured – in case of HSS tools like drills, milling cutters.

- during the time when they are being manufactured by powder metallurgical process – e.g., throwaway type inserts of carbides, ceramics and cermets.

Need and Purpose

Continuous chips are produced by continuous machining processes like turning of ductile metals, unlike brittle metals like grey cast iron, that leads to their disposal and handling problems. When ductile but strong metals like steels are machined at high cutting velocity for high material removal rate by using flat rake face type carbide or ceramic inserts, the problems become acute.

The sharp edged hot continuous chip that comes out at very high speed becomes dangerous to the operator.The other people who are working in the airspace may spoil or damage the finished surface by entangling with the rotating job, creating problems in chip disposal. Hence it is essentially needed to fracture such continuous chips into small pieces for safety of the people who are working, which will lead to the prevention of damage of the product, easy collection and disposal of chips. Improvement of machinability is done by reducing the chip-tool contact area, cutting forces and crater wear of the cutting is done in the proper way is the additional purpose of chip breakers.[16]

Dependence of chip formation in machining

The process of step-wise removal of excess material from the preformed blanks in chip forms is called machining.

The form of machined chips depend mainly upon : • The material of the work and cutting tool • Cutting tool geometry • Velocity and feed of cutting • Coolant that affects temperature and friction produced at the chip and work-tool interfaces. [17]

Actual Chip Forms and Classification

Desired

- C-Type Broken Chips

- Short Helical Broken Chips

- Medium Helical Broken Chips

- Large Helical Broken Chips

Not Desired

- Long Helical Unbroken Chips

- Long and Snarled Broken Chips

Chip formation in various processes

Chip formation in cast iron

The chip formation for cast iron is directly affected by the presence of graphite, which is known to have low mechanical strength and generate discontinuities and stress concentration effects in the matrix, in turn helping the material removal process. The chip formation mechanism is shown in the figure for gray iron and ductile iron. At the start, the tool compresses the material underneath the flank creating a fracture, which propagates ahead and beneath the cutting edge (a). As the cutting motion of the tool proceeds, the material fragment is completely detached (b). For some situations, especially with gray iron, a piece of material is tear off ahead of the tool, causing a temporarily lost of contact between tool and workpiece, until the next chip (c). The tear of material contributes for the higher surface roughness of the workpiece (d). For ductile cast iron the permanent strain is larger and the tear of material smaller (Cohen et al., 2000). The chip formation behavior for the compacted graphite iron lies between the ductile and gray behaviors (Reuter et al., 1999).[19]

Chip formation in twist drill

The twist drill working is based on the principle of chip formation, just like any other cutting tool in metalworking.

Chip formation is controlled mostly by the rake angle of the cutting tool. Rake is basically the angle of the cutting face relative to the axis of the tool. When the cutting face slants ahead of the cutting edge, this is termed as negative rake. Any time the cutting edge is ahead of the cutting face, this is termed as positive rake.[20]

References

- ^ McKenzie also used the terms Type I and Type II chips, although confusingly these are not the same as Franz'.

- ^ Atkins, Anthony G. (2008). The Science and Engineering of Cutting. Butterworth. p. 102. ISBN 075068531X. http://books.google.co.uk/books?id=sl3imKj8258C&pg=PA102.

- ^ Lee, Leonard (1995). "Appendix 1: Chip Classification". Complete Guide to Sharpening. Taunton Press. pp. 229–234. ISBN 1561581259. http://books.google.co.uk/books?id=CtkWaJw5iXkC&pg=PA229#v=onepage&q&f=false.

- ^ Fritz Klocke. "Lathing,Milling, Drilling.". http://books.google.co.in/books?id=Kcdbs_dwLFUC&pg=PA49&lpg=PA49&dq=different+types+of+chip+formation&source=bl&ots=tqNEzIRVYE&sig=g2oPua_DqoGFYn-jaEeUKjcn3SA&hl=en&ei=axaGTsbLLMOmrAf8sK26DA&sa=X&oi=book_result&ct=result&resnum=1&ved=0CB0Q6AEwADgU#v=onepage&q=different%20types%20of%20chip%20formation&f=false.

- ^ Hoadley, R. Bruce (2000). Understanding Wood: A Craftsman’s Guide to Wood Technology (2nd. ed.). Taunton Press. pp. 162–163. ISBN 1-56158-358-8. http://books.google.co.uk/books?id=5HBH2ibu-ZwC&pg=PA163.

- ^ a b Steve Elliott. "Shaving Formation". http://planetuning.infillplane.com/html/shaving_formation.html.

- ^ "Chip Formation Theory". http://www.efunda.com/processes/machining/chip_formation_1.cfm.

- ^ "aluMATTER". http://aluminium.matter.org.uk/content/html/eng/default.asp?catid=147&pageid=2144416178.

- ^ "Mechanical 360- Chip Formation- Machining". http://www.mechanical360.net/m-p/mechanism-chip-formation-machining/2/.

- ^ "ASM INTERNATIONAL- Chip Formation Mechanics". http://www.asminternational.org/portal/site/www/AsmStore/ProductDetails/?vgnextoid=b8317e0e64e18110VgnVCM100000701e010aRCRD.

- ^ a b c d e "Chip Formation- Suwa Precision Group". http://www.suwaprecision.com/machining/machining_technical_articles.html.

- ^ a b c d "Machining and Metrology". http://mmu.ic.polyu.edu.hk/handout/0102/0102.htm#9.

- ^ a b c Nageswara Rao Posinasetti. "Manufacturing Tooling and Cutting Tool Design". http://www.uni.edu/~rao/Mfg%20Tooling%20-03%20Cutting%20tools.pdf.

- ^ a b K. C. JAIN, CHITALE A. K.. "Theory of Metal Cutting". http://books.google.co.in/books?id=wPAxycRAHjUC&pg=PA80&lpg=PA80&dq=direction+of+chip+flow+in+oblique+cutting&source=bl&ots=8J4UbOOMR1&sig=KeYgG3855czqVtG0HpvaTJo2NfQ&hl=en&ei=0aehTv2IGcqGrAfCzPWNAw&sa=X&oi=book_result&ct=result&resnum=9&ved=0CGQQ6AEwCA#v=onepage&q=direction%20of%20chip%20flow%20in%20oblique%20cutting&f=false.

- ^ Beechmont Crest Publishing. "Calculating Depth of Cut for Lathe Operations". http://www.beechmontcrest.com/depth_of_cut.htm.

- ^ "Feeds and Speeds". http://www.efunda.com/processes/machining/chip_formation_2.cfm.

- ^ IIT Kharagpur. "Use of chip breaker in machining.". http://www.scribd.com/doc/11621416/7-Use-of-Chip-Breaker-in-Machining.

- ^ "Mechanics of machining, IIT Kharagpur". http://nptel.iitm.ac.in/courses/Webcourse-contents/IIT%20Kharagpur/Manuf%20Proc%20II/pdf/LM-05.pdf.

- ^ Nikhil R. Dhar. "Theory of Metal Cutting". http://www.scribd.com/doc/17283346/Theory-of-Metal-CuttingTheory-of-Chip-Formation.

- ^ "Scielo Brazil". http://www.scielo.br/scielo.php?pid=S1678-58782004000100004&script=sci_arttext.

- ^ "Modern Machine Shop". http://www.mmsonline.com/articles/widening-interest-in-twist-drills.

Categories:- Cutting tools

- Cutting processes

- Woodworking

- Metalworking

Wikimedia Foundation. 2010.